Cost Effectively Monitor Equipment

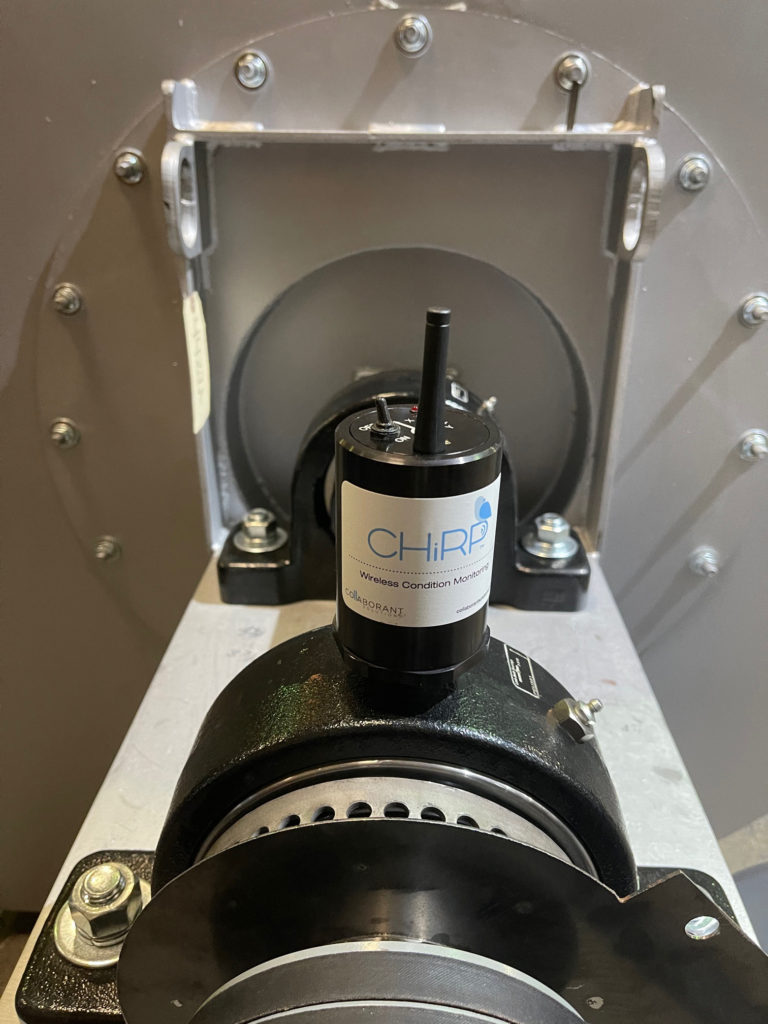

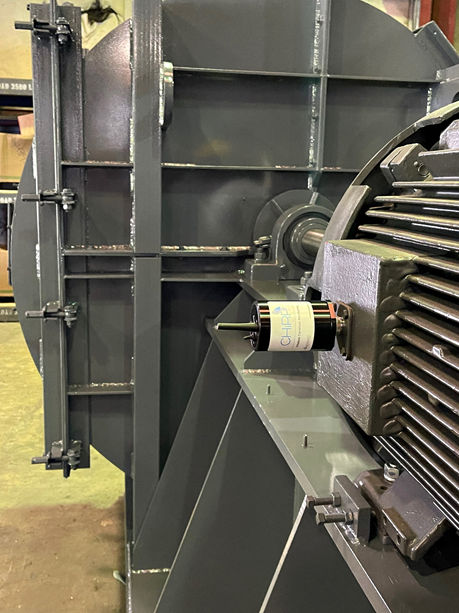

Attach battery-powered sensors to monitors and link wirelessly to the cloud. You don't buy, install, or maintain your own sensors and software. You pay a per-sensor monthly fee instead — predictable, no matter how many motors you monitor, or how often.

Why Use Predictive Maintenance?

Predictive maintenance can be a great cost saver. You avoid unnecessary service costs and spot equipment problems early — eliminating costly repairs and disruptions to business. On-location monitoring is expensive. You need to purchase and maintain equipment as well as pay a technician to visit each piece of in-service equipment you monitor.

How It Works

You simply attach the magnetic base of the sensor to a motor and start collecting and analyzing the motor's performance data on any web browser. Whether you monitor one motor or thousands, monitoring the performance never degrades and you receive instant alerts if a monitored value on any motor exceeds a set threshold.